Secure Your Products with Advanced Packaging Foil Solutions

RVX is a leading manufacturer of pharmaceutical packaging foil in China, offering professional and high-quality products to meet your needs.

Rvx Pack, established in 2009, is a company specializing in the production and sales of pharmaceutical packaging foil. Our extensive range of packaging foil products includes aluminum foil, aluminum aluminum foil, blister foil, cold forming foil, strip foil, pvc film, We take pride in offering professional printing customization services for these products and provide support for customers requiring small sample quantities for testing purposes.

Our company is equipped with state-of-the-art machinery, including gravure printing machines, dry compound machines, coaters, and slitting machines, ensuring high-quality production standards. Additionally, we have a dedicated team for professional testing and after-sales service. With a wealth of experience in the production of packaging foil, we have established close collaborations with numerous pharmaceutical companies. We welcome and encourage customers from around the world to visit our facilities and look forward to the opportunity to collaborate with you.

Custom any packaging foil for your project

![]() Provide professional technical advice and support to get samples through on-board testing quickly.

Provide professional technical advice and support to get samples through on-board testing quickly.

![]() Depending on the size you need, we can slit packaging foils with precision for small and medium batches.

Depending on the size you need, we can slit packaging foils with precision for small and medium batches.

![]() Our sales specialists follow up on every project and we have many years of experience in the fields of packaging foils and PVC/PE/PVDC. We will work with you to find the best solution if there is a problem.

Our sales specialists follow up on every project and we have many years of experience in the fields of packaging foils and PVC/PE/PVDC. We will work with you to find the best solution if there is a problem.

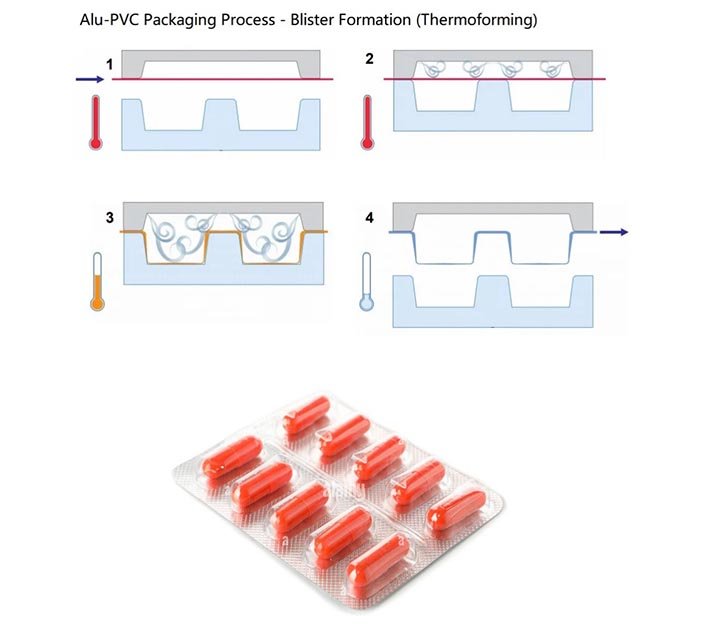

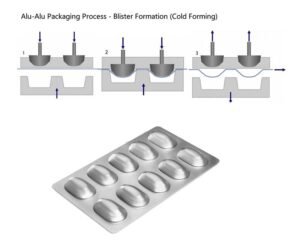

Our packaging foils for thermoforming blister packaging and cold-forming blister packaging in the pharmaceutical sector

Designed for thermoforming and cold-forming blister packs, our foils are highly moldable during thermoforming and can be precisely matched to different shapes of products to ensure a tight fit and improved sealing effect. Meanwhile, in cold-forming blister packaging, the high tensile strength and puncture resistance of the packaging foil effectively protect the product from external damage, ensuring product integrity and safety. In addition, our packaging foils have excellent barrier properties, which effectively extend the product’s shelf life and maintain its freshness and quality, making them the ideal packaging choice for you.

PVC/PVDC/PE and PVC/EVOH film for medical and food packaging

Our company specializes in the production of high-quality laminated PVC rigid sheets and films, which are widely used in packaging for food and pharmaceuticals. Through advanced production processes and strict quality control, our PVC rigid sheets and films have excellent transparency, strength, and safety, which can effectively protect the products inside the package from the external environment and ensure the quality and safety of food and pharmaceutical products.

We strictly control the production process to ensure that each piece of PVC rigid sheet and film meets the safety standards, giving consumers a reassuring experience.

Packaging Foils for Yogurt Cup

Our company focuses on producing high-quality aluminum foil for yogurt lids, and with advanced technology and precise manufacturing processes, we ensure that each piece of aluminum foil has excellent performance. Our aluminum foil lids are widely used for packaging all kinds of yogurt products. Our aluminum foil for yogurt lids has excellent heat sealing performance, which enables efficient sealing and ensures that yogurt is protected from external contamination during transportation and storage, maintaining fresh taste and nutritional value. Adopting a multi-layer composite structure, it has excellent gas barrier and tear and abrasion resistance, effectively preventing oxygen from entering the package and avoiding oxidization and deterioration of yogurt. We offer a wide range of specifications, thicknesses, and printing design services to meet the packaging needs of different products and enhance their market competitiveness.

Advanced Production Quality Management

Our company is committed to providing high-quality pharmaceutical packaging foil materials. We have safe and efficient production equipment, strict workshop environment control, and advanced production processes to ensure that each batch of products meets the international standards for pharmaceutical packaging and fulfills the high requirements of the pharmaceutical industry.

We are equipped with many advanced automated production equipment, including fully automatic coating machines, laminating machines, printing machines, cutting machines, etc. The equipment adopts a precision control system to ensure the production process is stable and efficient. Our production workshop strictly follows the requirements of GMP (Good Manufacturing Practice), and the workshop is equipped with an advanced air-conditioning purification system, where dust, microorganisms, and other harmful substances in the air are strictly controlled to ensure the cleanliness of the packaging materials. Environmental parameters such as temperature and humidity, cleanliness, etc. in the workshop are strictly monitored to ensure that each process is carried out under optimal conditions. From the selection of raw materials to the finished product, every step of the process is subject to strict quality inspection and control. Our production process includes material pretreatment, laminating, printing, coating, cutting, etc., and each step is equipped with professional technicians. Our products are widely used in all kinds of pharmaceutical packaging, and after years of market verification, won the trust and praise of our customers.

Company Values

- Create and Deliver next in class Pharmaceutical Aluminium Foil Packaging solutions.

- Manufacture quality and cost competitive products for its customers.

- Ensure safe and contamination free products.

-

-

Team Member

-

-

National Award

-

-

Client Happy

-

-

Project Done

- 2024-6-5

Alu Alu Foil Printing Machine

Alu Alu foil printing machines play a crucial role in the pharmaceutical packaging industry, as well as in food and beverage packaging, c...

Load More- 2024-6-5

Alu foil& Blister Tropical foil for Pharmaceutical Packaging

Alu foil is an integral component of pharmaceutical packaging, thanks to its unique properties that help ensure product safety, efficacy,...

Load More- 2022-5-21

Requirements of soft packaging film materials for drugs

The requirements for pharmaceuticals on flexible packaging film materials are as follows: To prevent the deteriorat...

Load More